Heat dissipation from hydraulic oil tanks valves pipes and hydraulic components is less than a few percent in standard mobile equipment and the cooler capacity must include some margins.

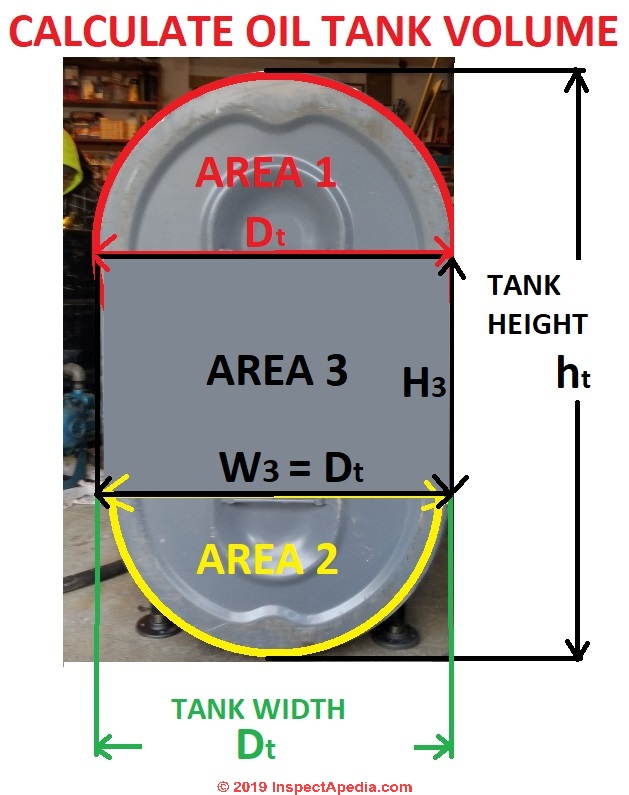

Oil cooler capacity calculations.

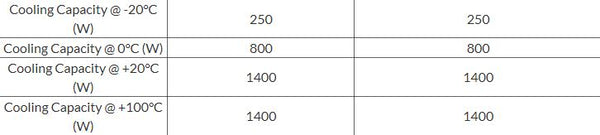

Oil cooler with dc motor 12v 24v.

Therefore our product selection is continuously changing.

Calculation of preliminary cooler capacity.

Oil cooler with ac motor 400v oil cooler with hydraulic motor.

A continual desire for more cost efficient and environmentally friendly hydraulic systems requires continuous development.

Using the energy equation of q ṁ x cp x δt we can calculate the cooling capacity.

This is almost impossible to calculate but can be estimated based on the type of system and the components used.

Minimum cooler capacity ecooler 0 25ediesel.

Areas we are continuously seeking to improve performance include cooling capacity noise level pressure drop and fatigue.

Q 999 78kg m3 x 0 0995m3 s x 4 19kj kg k x 12 c 273 15k 6 c 273 15k we add 273 15k to the celcius to convert it to units of kelvin.

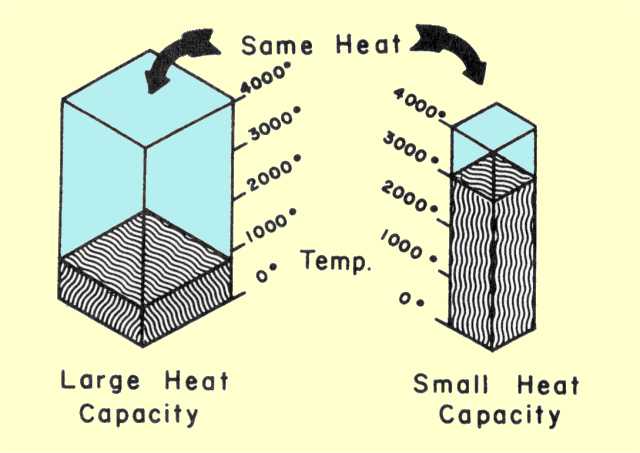

The specific heat capacity cp is measured in units of kj per kg per kelvin.

The next thing to consider is the native efficiency of the system.

Iso vg 68 oil flowing at 40 gpm and a desired cooling capacity qr 40 hp.

/stories/2018/08/438801.jpg)